Model: LD-300AX/430AX

Packaging materials: Multilayer Composite Premade Bag(e.g.: PET/PE).

Bag Type: 3-side-seal, gussette pouch, standup pouch no-zip-lock.

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate).

1-15 bags/min

Model: LD-300AX/430AX

Packaging materials: Multilayer Composite Premade Bag(e.g.: PET/PE).

Bag Type: 3-side-seal, gussette pouch, standup pouch no-zip-lock.

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate).

1-15 bags/min

● Application: by connecting with different weighing equipments, the packing system can handle various products, such as candy, seeds, snacks, dried vegetable or fruit, puffed food, liquid sauce, beverage, etc.

● Bag Style: Suitable for all kinds of the premade bags, such as stand up pouch, zipper bag, box pouch, kraft paper bags, corner spout bags and so on.

● Kindly Reminder: We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

● Automatic checking: no pouch or pouch open error, no fill, no seal, avoid wasting.

● Safety device: Machine stop at abnormal air pressure, heater disconnection alarm.

● Adjustable bag width.

● Glass safety door: It will stop working when you open the door, ensure the safety of operators.

● Low loss of packing materials, high quality of the sealing part, to improved the product specification.

● Different feeding hoppers: for solid, liquid, thick liquid ,powder and so on.

● Bag materials: Suits in extensive range.

Model | LD-DGW-350 |

Bag Width | 80-280mm |

Bag Length | 80-350mm |

Bag Type | Stand up pouch, Pillow bag |

Power Supply | 220V/380V, 50/60HZ |

Air Consumption | 7.0 CFM@80 PSI 0.14m3/m3 |

Pneumatic Parts | PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan |

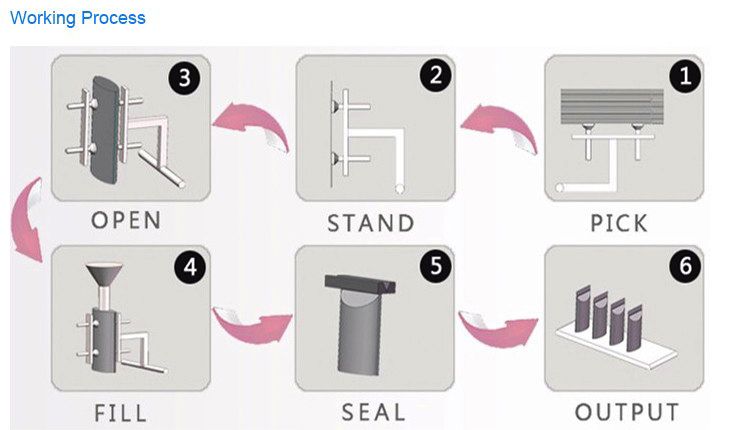

●BAG OPENINHG

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated to the fill area and opened.

●TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch detection the chute enters the bag and opens its gate. Product is dispensed immediately, without spillage and protecting the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through the "open-gate''

●FILLING

During filling, pouches are held in place with our "posi-hold" gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

●SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place" eliminating wrinkles, folded corners and non aligned seals

After receiving your inquiry, We will send you the quotation as soon as possible.