Tips To Choose A Right Powder Packing Machine

Powder, a common product in our lives, contains Medicine powder, food powder, chemical powder, etc. The powder has different thicknesses, the thickness of the powder is generally distinguished by the number of meshes.

Such as Normal flour powder: 80 mesh; refined flour: 120 mesh; bread flour: 140 mesh. The finest flour is 140 mesh.

That means. The larger the mesh number, the finer the material particle size; the smaller the mesh number, the larger the material particle size.

We need to consider the following two points.

A: The First step is confirming the feature of powder.

So we should understand the density of the powder before recommending the right dosing system. Generally, We recommend a screw metering device as a dosing system for dry & fine powder to ensure high metering precision.

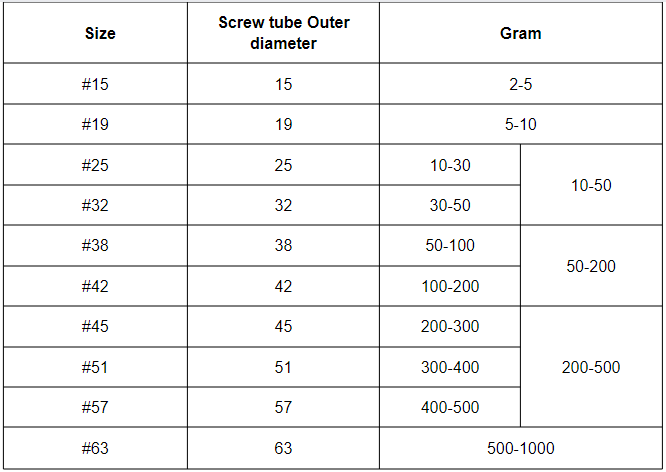

Please refer to the picture of the screw below:

As you can see each screw has a different diameter, Screw is rotated by a servo motor to measure the target weight of the powder. In order to keep the high metering precision and metering speed. We suggest you prepare more screws to meet your different bag capacities. Here is the list of screw sizes for your reference.

The packaging machine that uses screw measurement has different measurement methods for different materials. For example, for some materials with poor fluidity such as flour and starch, we recommend using a vertically elongated screw to ensure the accuracy of the finished product packaged by the powder packaging machine. It is tall and beautiful in appearance. A good effect has been achieved.

When the powder packaging machine packs materials with good fluidity, such as fine salt. It is recommended to use a flat screw for measurement. This not only solves the problem of measurement accuracy, but also solves the problem of dripping materials, and the use effect reaches customer satisfaction. When the powder packaging machine uses a screw for metering, it should be based on different material properties.

B: The next step is to determine the general functions of the powder packaging machine.

To ensure the powder packing machine with good working performance. Those functions are necessary. Such as:

1. Anti-leaking device

2. Dust removes the device.

If you plan to pack pharmaceutical powder products, As the requirements for pharmaceutical powder packaging are relatively strict, powder packaging is often chosen in a dust-free workshop, in order to ensure a good packaging environment, avoid the secondary pollution to the pharmaceutical powder, and reduce the working environment Under the dust pollution. The packaging machine must be equipped with an anti-leaking device and a dust removal device.

Some powders are relatively dry, and static electricity will be generated between the powder and the packaging film during the metering and blanking process. Generally, we recommend adding a static elimination device to the packaging machine, or recommend that customers use Aluminum laminated film. Like PET/VMPET/PE.

For more customized packing solutions .please feel free to contact LANDPACK!