Foshan Landpack Machinery is with about 13 years history, located in Foshan City, China. We concentrate on research and development, manufacturing, installtion, commissioning and technical service, the products including vertical packing machine, horizontal flow packing machine and varies automatic feeding abd packing lines, and so on. We ever exported to America, Russia, Europe, Middle East, South Asia, Africa, South America, and so on, more than 30 countries and regions.

The machine have been widely apply in food, agricultural products, industrial supplies, daily necessities, etc. As an advanced packaging equipment manufacturer, we are committed to providing professional packaging solutions for enterprises, which can make the packine process get a qualitative improvement, greatly save labor, avoid secondary pollution, improve production efficiency in an efficient way.

Now I would like to introduce you about one of our hot sale machine--LD-8200A pre-made packing machine.

The whole machine is composed of three parts: Z type conveyor, multi head weigher, support plamform and the main packer. Now I will introduce them in separate.

It can pack for block material, like curd cake, candy, chocolate, biscuit, peanut, and so on, granular type like seeds, nuts, sugar and so on. The preformed bag can be in pouch bag, bag with zipper....

Let’s see the first part, this is the Z type conveyor, it can transport the products to the weigher with its vibration function. The height of it can be customized by customers requirements, the materail also have carbon steel and stainless steel. Look at this little transportation hopper, their materal is PP, can for food, and if you want it for chips, meats and so on, some will have oil stain, with this hopper, it will be easy to clean, because each of them can be separate, and easy to intall.

The multi heads weigher, there have a sensor on the top of the material table, if there are too many products, the conveyor will stop transport prouduct into the weigher, and the lack of materials can be automatically suspended to make the weighing more stable. The working principle is through computer calculation, with the perfect combination of high precision and high speed, the best weight combination is instantly selected from the rich weight combination to achieve the preset weight. The high-precision digital sensor can achieve accurately measure. the accuracy is 1-1.5g.

It control by the touch screen, will be more easier to operate. All the parameter and function can be set in the touch screen. And it have 15 language can be choose.

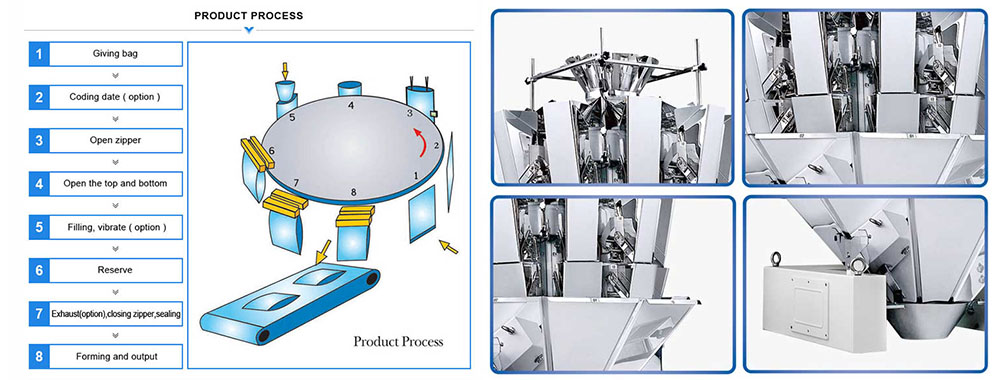

The final part is the main packer, there have 8 working station, : giving bag, coding, opening, filling 1, filling 2(Option), exhaust(Option), heating sealing, forming and output product, will like below photo:

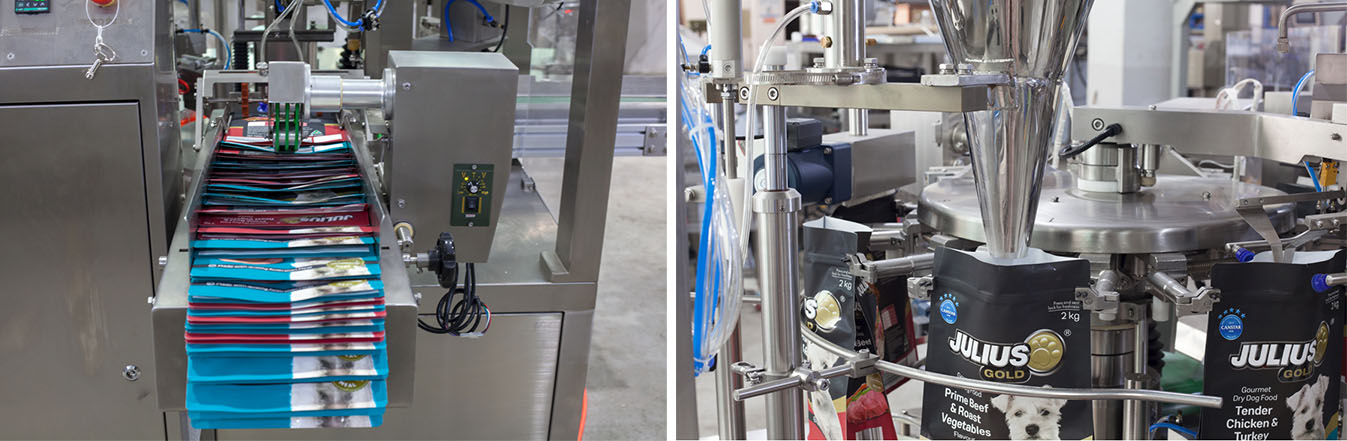

You can put the bag in this magazine horisontal, can change the bag length and bag width by the handle, easy control. It transport the bag by this robot hand, it control by cylinder, it will more steady and make sure the rate of giving bag.

The second station is an option location, the standard option is date printer, you can print 45 character outside the bag.

The third station, is the bag open staion, different for the pre-made bag and zipper pre-made bag. For zipper bag, it have 6 sucker in here to open the zipper, each sucker with cylinder, to make sure it can open the zipper in the best performance, and with the help of these two clamp, this is the bright point of this location, simulate human’s hand to open the zipper, to improve the rate to open the bag, the rate of success can up to 99%, and can suit for different thickness of bag.

The fourth station is the open bag location, it can open the bag in the top and below, and in the top, it have a blowing outlet, to make sure the bag will open totally, convenience for feeding.

Next is the feeding part, it with a supporting device below, to help the products feeding in best situation.

Then will be two option function, you can make it in secondary feeding, exhaust, dust, etc.

And we have the last two station is for forming and sealing.

Above are introduce of our machine, any question of our machine, please let me know freely.