The principle and advantages of the bag feeding machine:

Adopt imported PLC, man-machine interface and pneumatic components to complete packaging automation. Employees can put hundreds of bags into bags and use parts of the equipment at a time to deliver new products to industries like food, chemical plants, pharmaceuticals, seeds, and more. High quality service. Therefore, it is very important to choose the feeding bag packaging machine that suits you.

Today I will share LANDPACK three type rotary doypack machine with us ,

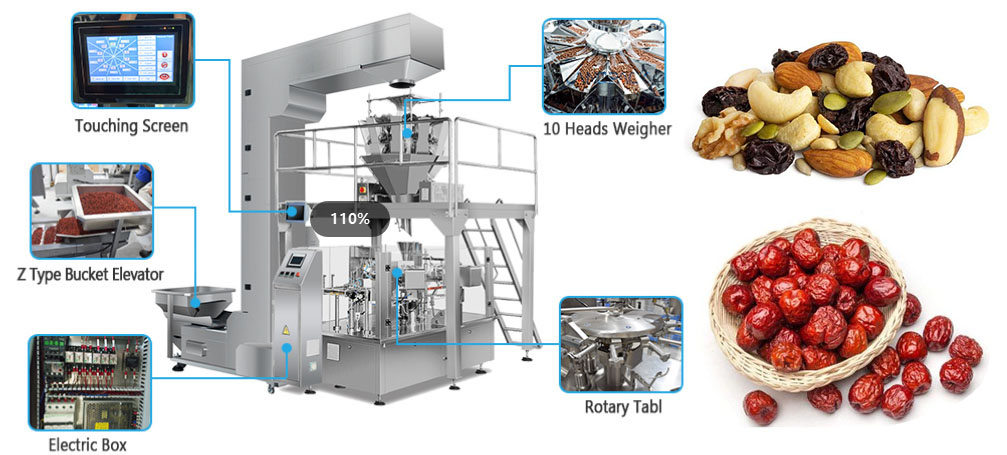

A.granule rotary doypack machine

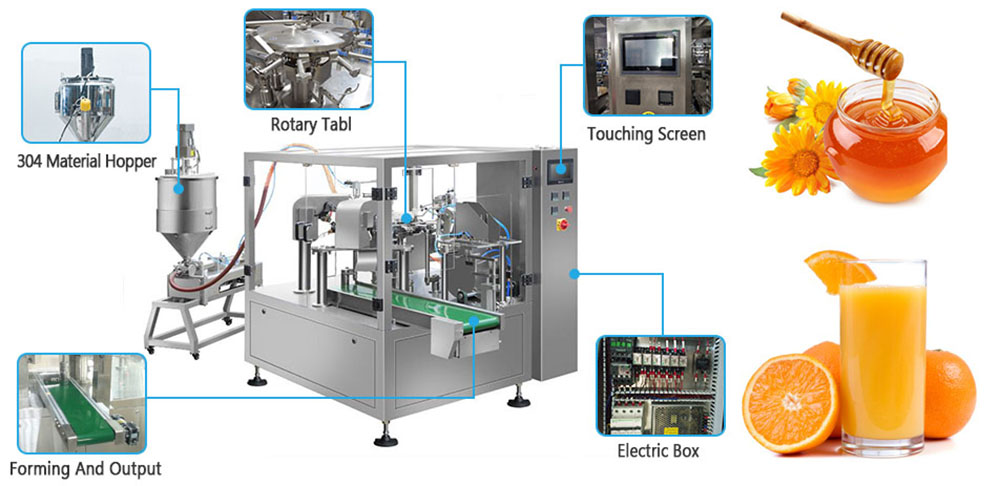

B.liquid rotary doypack machine

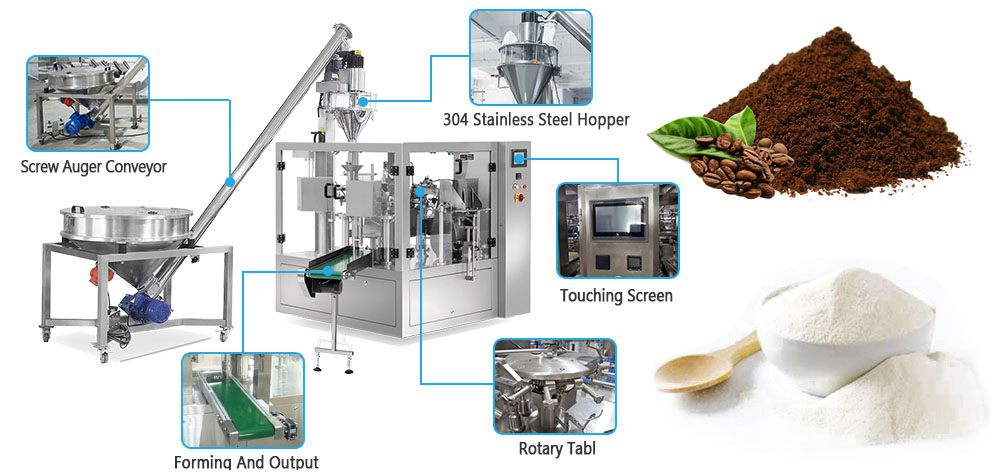

C.powder rotary doypack machine

Next I will introduce landpack rotary doypack machine advantage :

1. Comply with the technical specifications and requirements of food packaging, have obvious requirements for the materials and containers selected for food, ensure the quality of packaging and the production capacity of advanced packaging technology, safe and stable control, low energy consumption, and convenient maintenance;

2. Pay attention to the versatility of machinery, which can adapt to the packaging requirements of various foods. It's easy to clean and won't damage food.

3. Have a reasonable and reliable control system for the temperature, pressure, time, measurement, speed and other conditions required for food packaging, try to use automatic control methods, produce a single product for a long time, and use special machinery.

4.For multi-category, same-category and multi-standard products, a multi-functional bag feeding and packaging machine can be used. One machine can complete a variety of packaging operations, improve power, save manpower, and greatly reduce the total area. Effectively improve working conditions and reduce labor intensity

For a new user ,how to choose the rotary doypack packing machine Which aspects to consider?

To choose a good feeding bag packaging machine, we can analyze it from three aspects:

1. The service life of the equipment

A good bag feeding and packaging machine usually adopts a mechanical structure, the service life will be greatly improved, and the maintenance cost is low. Usually only need to refuel, tighten the screw to use. The use requirements are extremely low, and the equipment has a long service life. (8~10 years) If other structures are used, the equipment will usually have serious problems in about half a year (the service life of the equipment is about 2~3 years)

2. Equipment performance is stable

Before thinking about this, you need to understand your own needs for fully automatic bag feeding and packaging machines, meeting the technical needs of your business, and your needs for packaging materials and material containers for fully automatic bag feeding and packaging machines. Select so you can .. select. . product. The degree of automation of automatic bag feeding and packaging machines is generally relatively high, so the second point for enterprises to consider is whether the function of the equipment is stable and whether the quality of the equipment has passed the test. Low automatic feeding bag packing machine.

3. Energy costs

When choosing an automatic bag feeding packaging machine, pay attention to the versatility of the machine, which can meet the packaging requirements of various types and specifications of items, and produce a variety of multi-standard products. Use a multifunctional automatic bag feeding and packaging machine. One piece of equipment can complete a variety of packaging operations at the same time, saving labor costs, improving production efficiency and reducing site occupation. Seeing this, I hope you can also choose the feeding bag packaging machine suitable for your company.